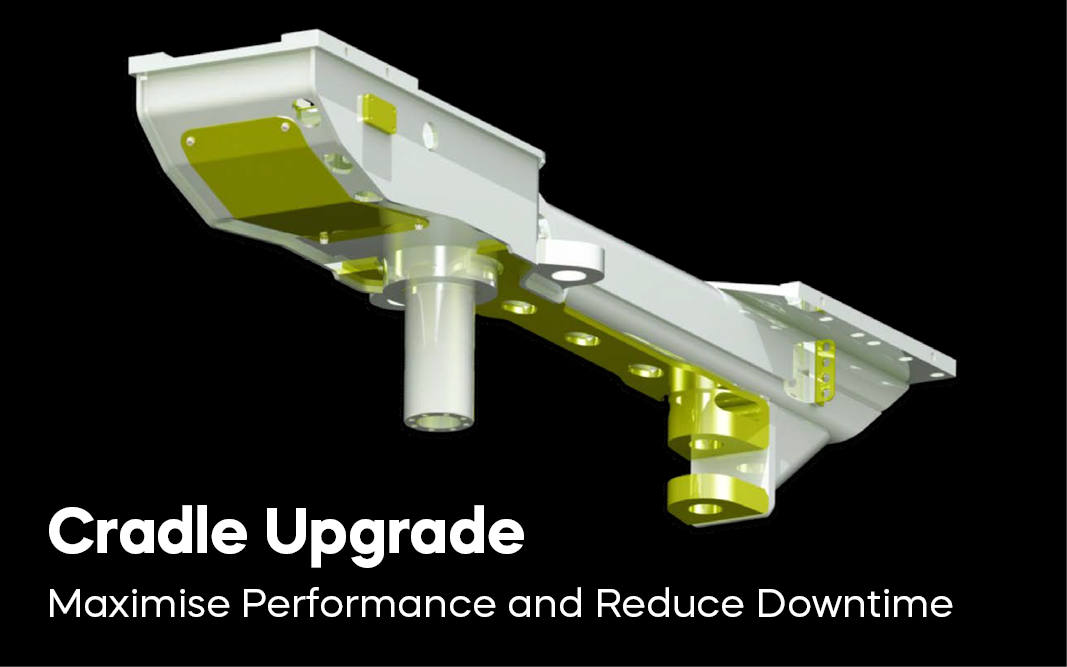

With its innovative design, advanced materials, and customer-focused engineering, MASPRO’s bolting cradle represents a superior solution for underground mining applications. From improved safety features to enhanced structural integrity and operational efficiency, this cradle is built to deliver unmatched performance. Designed to endure the toughest conditions, it ensures mining equipment operates at peak efficiency, providing a dependable solution that mining professionals can trust.

Product

Search

Search

Popular tags:

ACCOUNT

REQUIRED

REQUIRED

To access our full catalogue including stock availability, specs

and resources, please log in or register for an account.

and resources, please log in or register for an account.

LOGIN

REGISTER

Thank you for registering

Our team is currently reviewing your application. You will

receive an email confirmation soon.

receive an email confirmation soon.

Bolting

CRADLE ASSEMBLY

OEM Part No: BG00370652ASSY

MASPRO Part No: 010201008

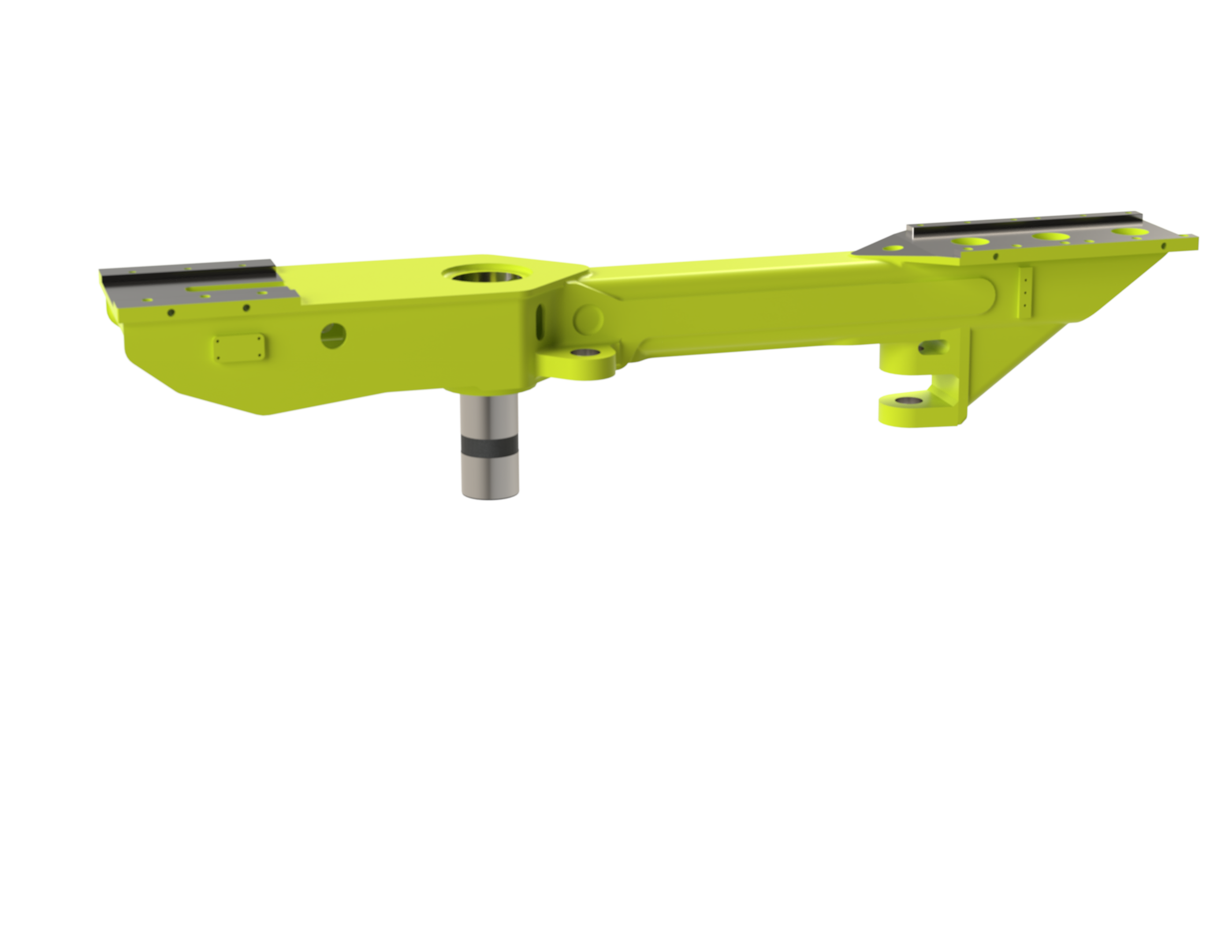

Cradle and Pipe Assembly has been designed and manufactured as a solution for issues experienced with competitors’ products in the bolting application of the SB60 Jumbos.

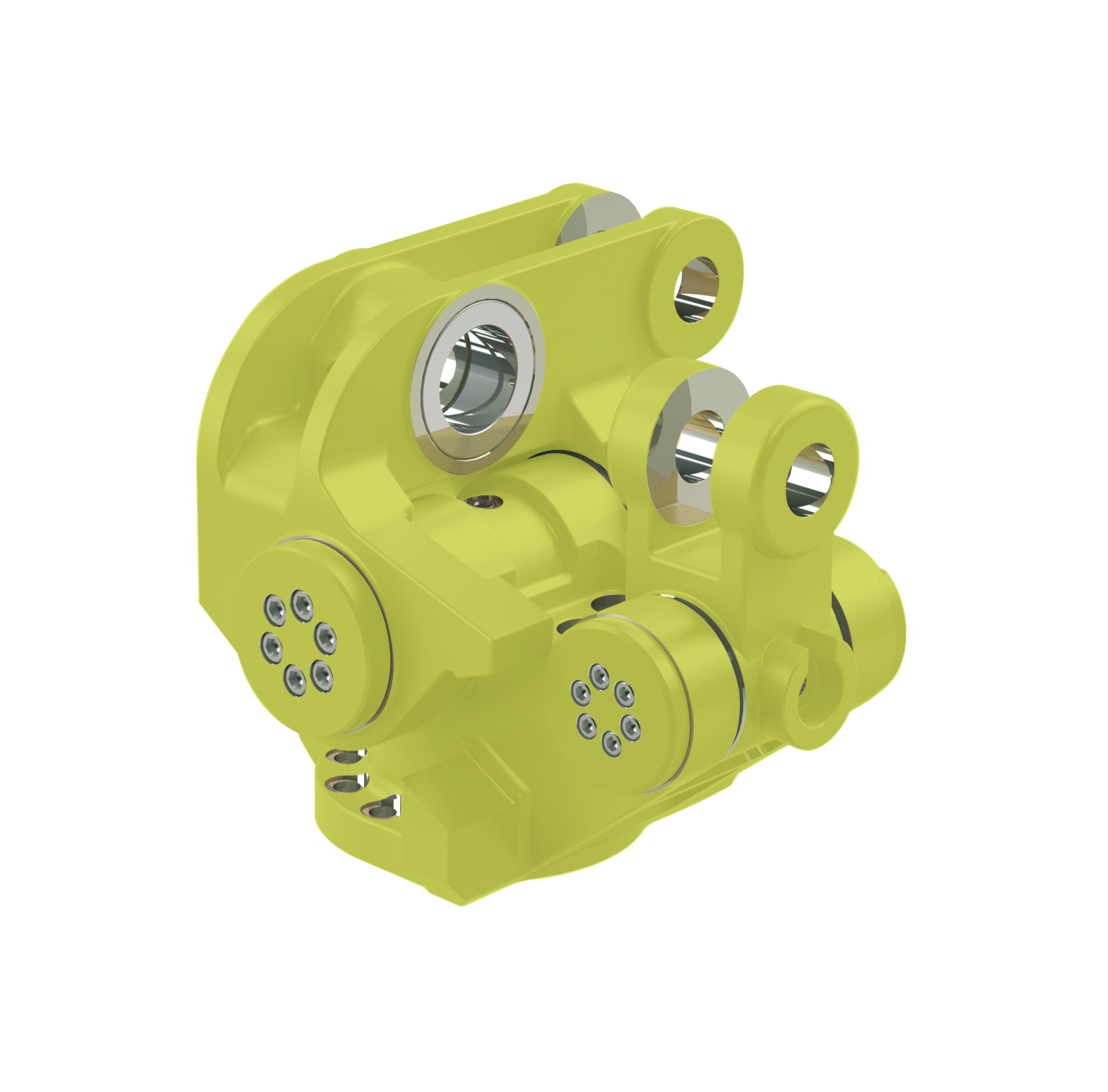

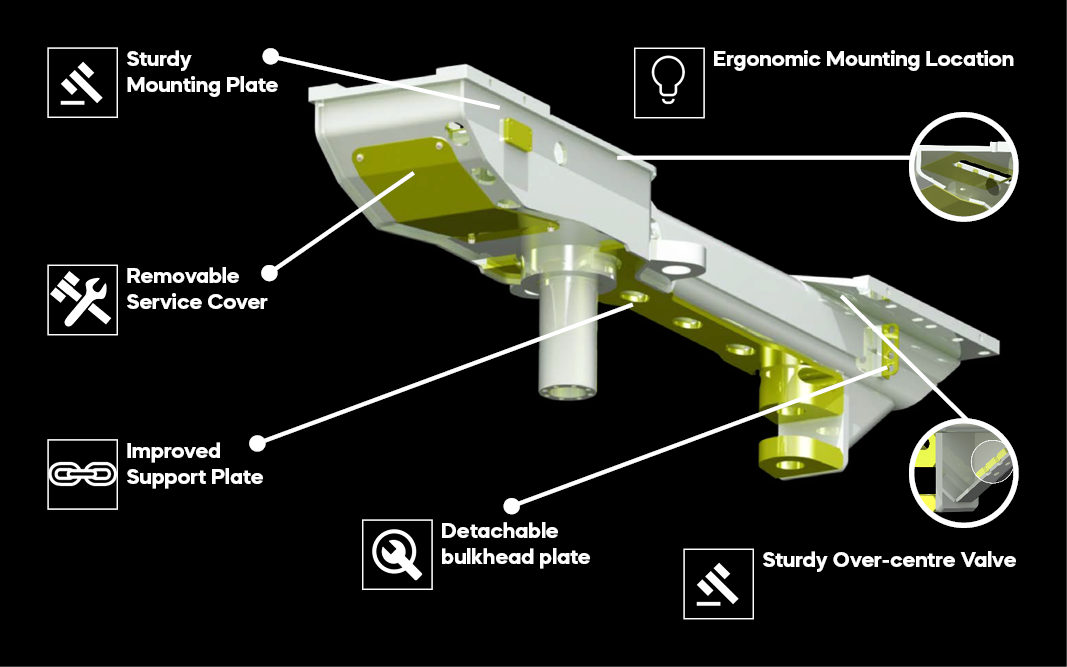

Constructed using specialist alloys, this cradle is engineered to withstand the high fatigue stresses encountered in underground mining operations. By utilising materials specifically selected for their durability, MASPRO has developed a solution capable of enduring repetitive stress conditions while maintaining optimal performance.The cradle weldment is fabricated to maximise fatigue life, ensuring it meets the rigorous demands of mining environments. One of the standout safety features is the upgraded pivot shaft, which incorporates a drop safety mechanism. This enhancement reduces the risk of the feed assembly detaching from the rollover effectively addressing a critical safety concern. MASPRO’s cradle is also highly versatile, designed for compatibility with both SB60 and TB60 Booms, making it a reliable choice across various applications.

Precision Engineering

At MASPRO, precision engineering is at the heart of every product. This approach reflects our commitment to providing safe, reliable, and productive solutions tailored to our customers’ needs. By collaborating closely with clients, we gain direct insights into their operational challenges and incorporate these considerations into our designs. This customer-centric process ensures that every MASPRO product is optimised for performance and durability while addressing recurring failures commonly seen in OEM components. Our engineering team employs state-of-the-art tools and methodologies to continuously refine and enhance our designs. By integrating advanced materials and collaborating with industry partners, MASPRO’s products consistently outperform industry standards, extending operational lifespans by up to tenfold. In addition, our pre-assembled solutions are designed for seamless integration into existing operations, reducing downtime and delivering trusted performance in demanding environments.

Structural Integrity

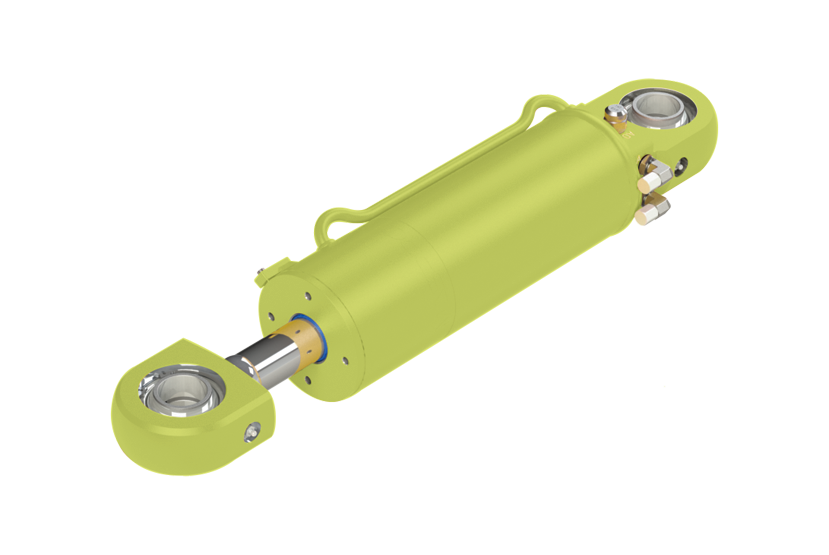

The redesigned support plate and bolting clevis strengthen the connection between the hydraulic cylinder and the cradle, ensuring a robust and resilient interface. These enhancements allow the cradle to better withstand the intense forces and vibrations experienced during mining operations. The result is a longer-lasting component that minimises the risk of operational disruptions caused by structural failures. This focus on durability ensures that MASPRO’s cradle maintains consistent performance under even the harshest conditions.

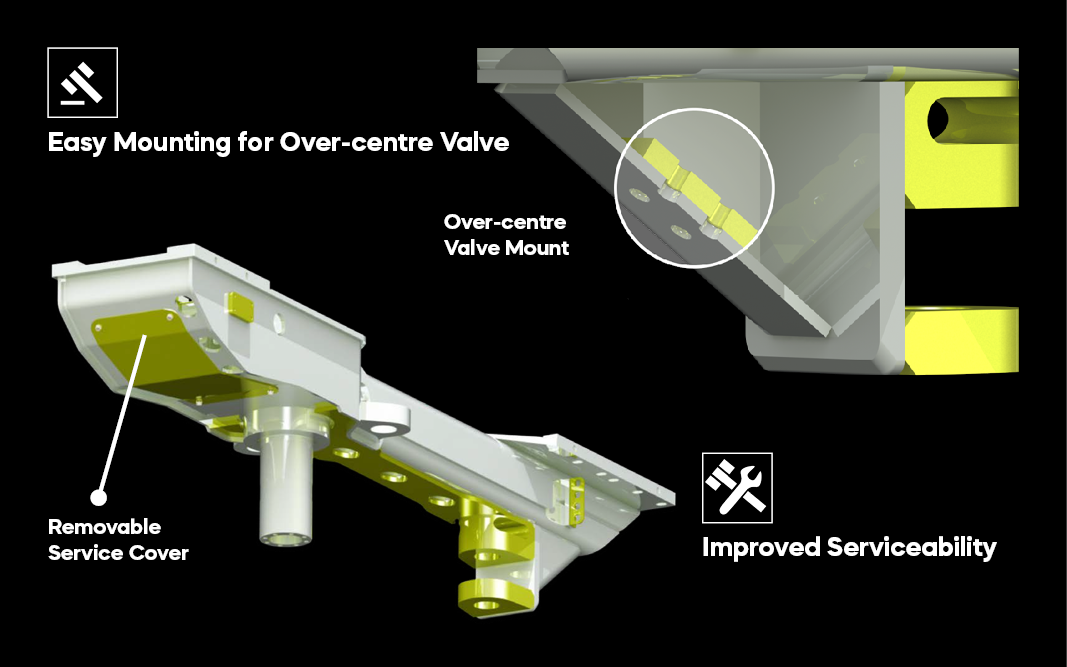

Safety & Reliability

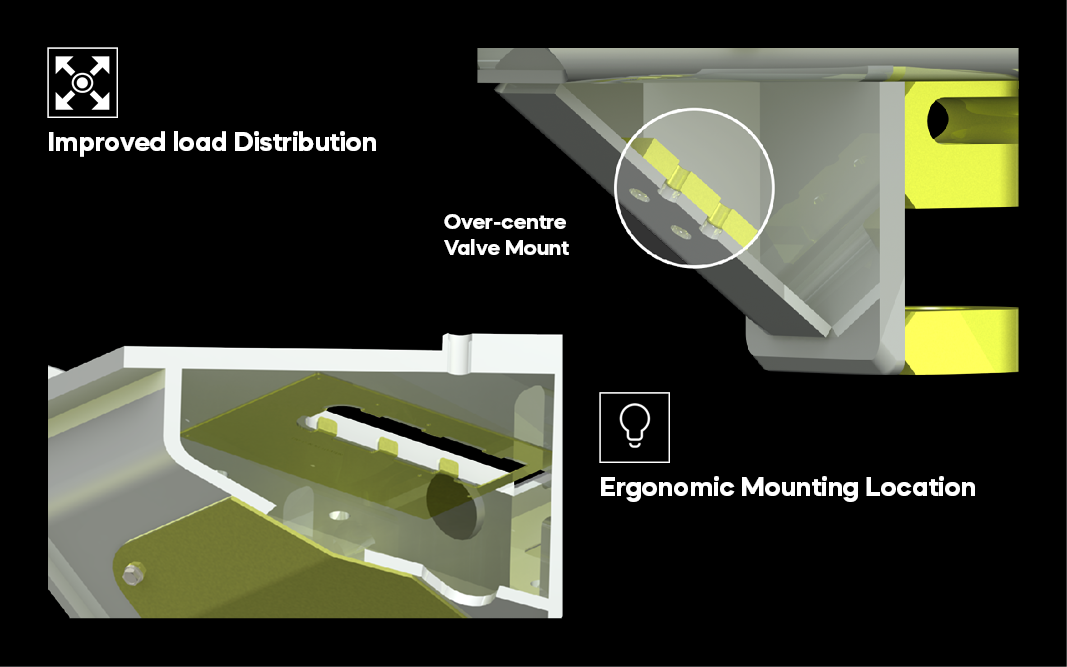

With the introduction of an easy mounting solution, the over-centre valve now attaches to a robust backing plate, engineered to withstand the vibrational forces encountered during operation. This upgrade not only ensures secure mounting but also safeguards against potential thread stripping, guaranteeing a reliable and long-lasting installation that contributes to the overall durability and performance of the system. A removable service cover now shields the entire rear section, safeguarding it from large debris during operations where the cradle isn't in a horizontal position. This protective measure enhances the system's serviceability by simplifying access to rear components for maintenance tasks, ensuring quick and efficient servicing without compromising operational efficiency.

Operational Productivity

The introduction of reinforced mounting plates on both sides of the cradle has further enhanced operational productivity. These plates improve load distribution, reducing stress on individual components and creating a more durable and balanced system. This upgrade enables the cradle to accommodate higher loads without compromising structural integrity, resulting in longer service life and reduced downtime. By offering a robust foundation for component attachment, MASPRO’s cradle significantly improves the overall efficiency and reliability of mining operations.

GET IN TOUCH WITH OUR

Expert Team

| Australia | 1800 627 776 |

| International | +61 2 6895 2822 |

| Orders, enquiries & Technical Advice: | sales@maspro.com.au |