Boosting Efficiency with Robotic Welding: How Bertha is Transforming MASPRO’s Production

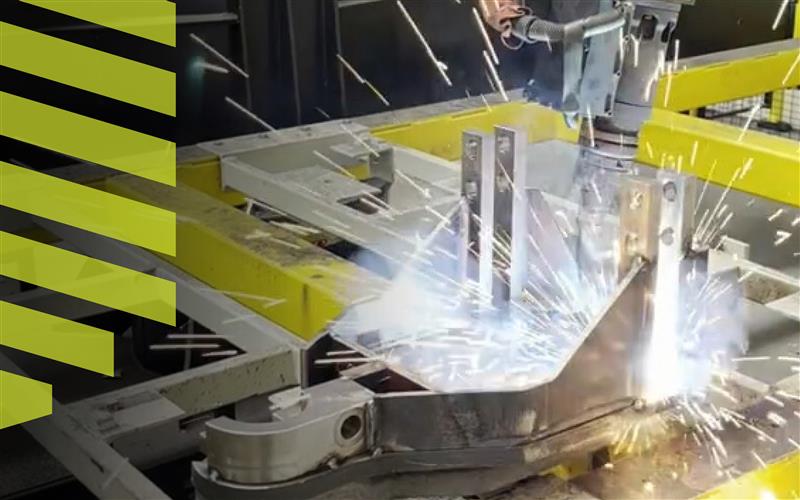

Innovation isn’t just about technology—it’s about the people who make it work. At MASPRO, we believe that the real power of automation lies in its collaboration with human expertise. Enter Andrew Brown, Samrat Adhikari, and Bertha (our Fanuc Robotic Arm-equipped X-Wing Welding Positioner). Together, they are redefining our welding process, combining cutting-edge automation with deep technical know-how to improve efficiency, precision, and product durability.

The Challenge: Transitioning from Manual to Robotic Welding

Switching from traditional manual welding to robotic automation wasn’t as simple as flipping a switch. One of the biggest challenges was adapting the welding process to Bertha’s capabilities. Unlike human welders, robotic systems require precise part positioning, specialized jigs, and advanced programming to execute perfect welds consistently. Andrew had to rethink the welding approach, ensuring that Bertha could replicate the same high-quality results as a skilled human welder but with increased efficiency. Meanwhile, Samrat worked with MOSES, a software application used for simulating robotic weld paths, offline programming, and generating weld sequences for Bertha. The learning curve was steep, but the results have been game-changing.

The Power of Through Arc Seam Tracking (TAST)

Our robotic welding system utilizes TAST (Through Arc Seam Tracking) to adjust for slight variations in joint position during welding. This ensures consistent weld quality by making real-time corrections

The Shift to Pulsed Transfer: Stronger, Cleaner Welds

Another significant improvement has been the transition from Short Circuit Transfer to Pulsed Spray Transfer. This switch has drastically improved the integrity of MASPRO’s welds by:

- Reducing Spatter: Short Circuit Transfer generates excess spatter, leading to more cleanup and potential defects. Pulsed Transfer minimizes this, ensuring a cleaner weld with less material waste.

- Controlling Heat Input: Since MASPRO works with heat-sensitive materials like chrome rods and quench & tempered metals, maintaining precise heat input levels is critical. Pulsed Transfer provides a better heat input through the use of as second lower background current, preserving the mechanical properties of welded components.

- Increasing Weld Strength: More precise control over heat input and penetration results in stronger, more durable welds, enhancing the longevity and reliability of MASPRO’s products.

Faster Production, Higher Quality

Before Bertha joined the team, welding a single front centraliser frame took 240 minutes. Today, with robotic automation and refined welding processes, that time has been cut to just 100–110 minutes per frame—a staggering 50% reduction. This efficiency gain allows MASPRO to produce more components in-house, reducing reliance on subcontractors and giving us greater control over quality and turnaround times.

The Impact on Welders, Machinists and Workflow

With Bertha handling high-precision welding, our welders and machinists have been able to focus on higher-value tasks, streamlining the overall production process. The increased efficiency means:

- More work completed internally, leading to faster delivery times.

- Greater alignment between machining and welding departments, improving workflow coordination.

- Enhanced job satisfaction, as machinists and welders engage in more strategic and technical aspects of production rather than repetitive tasks.

How our customers benefit:

These technological advancements aren’t just about making our operations more efficient—they’re about delivering superior products to our customers. Thanks to the seamless integration of human expertise and automation, MASPRO customers can expect:

- Faster Delivery: Reduced production times mean quicker turnaround for essential mining components.

- Enhanced Reliability: Stronger, cleaner, and more precise welds ensure components withstand the toughest conditions.

- Consistent Quality: Automation removes variability, ensuring every product meets MASPRO’s high standards.

The Future of Welding at MASPRO

This is just the beginning. With Andrew and Samrat continuously refining Bertha’s capabilities, MASPRO is committed to staying at the forefront of welding innovation. As automation and human expertise continue to evolve together, we remain focused on delivering superior mining components with unmatched confidence in quality.

Confidence in Quality, Engineered by Innovation

Our investment in automation isn’t just about speed—it’s about delivering reliability you can count on.

Get in touch